In response to the surging demand for electric vehicle charging infrastructure, manufacturers are increasingly turning to innovative materials to enhance efficiency and sustainability. Among these materials, 6101 aluminum alloy is gaining prominence for its remarkable properties tailored for charging station construction.

6101 aluminum alloy, renowned for its superior conductivity, strength, and corrosion resistance, is becoming the material of choice for crafting various components within charging stations. With its versatile characteristics, 6101 alloy ensures the reliability and longevity of charging infrastructure while contributing to weight reduction and cost-effectiveness.

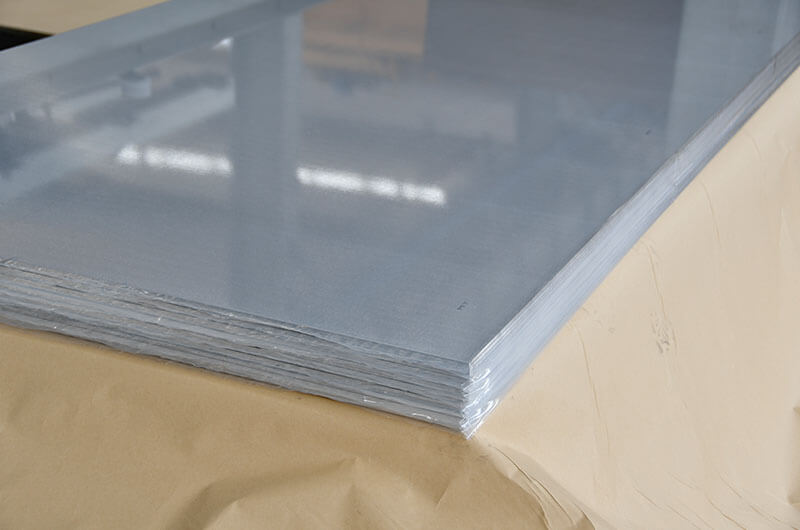

Specifications of 6101 Aluminum Alloy for Electric Vehicle Charging Stations:

Composition: 6101 aluminum alloy typically consists of approximately 97.9% aluminum, 0.6% silicon, 0.35% iron, 0.2% copper, 0.2% titanium, and trace amounts of other elements. This composition imparts excellent electrical conductivity and mechanical properties to the alloy.

Tensile Strength: The tensile strength of 6101 aluminum alloy ranges from 170 MPa to 200 MPa, ensuring structural integrity and durability in charging station components subjected to various loads and environmental conditions.

Conductivity: With a conductivity rating of approximately 56% IACS (International Annealed Copper Standard), 6101 aluminum alloy facilitates efficient power transmission within charging stations, minimizing energy loss and optimizing charging performance.

Corrosion Resistance: 6101 aluminum alloy exhibits outstanding resistance to corrosion, making it ideal for outdoor charging station installations exposed to moisture, pollutants, and other corrosive elements. This corrosion resistance extends the service life of charging infrastructure and reduces maintenance requirements.

Machinability: The machinability of 6101 aluminum alloy allows for precise fabrication of charging station components, ensuring dimensional accuracy and consistency during manufacturing processes such as cutting, drilling, and forming.

As electric vehicle adoption continues to soar globally, the utilization of 6101 aluminum alloy in charging station construction underscores a shift towards sustainable and efficient charging solutions. By meeting stringent specifications and performance requirements, 6101 aluminum alloy contributes to the advancement of electric mobility infrastructure, fostering a greener and more accessible future for transportation.