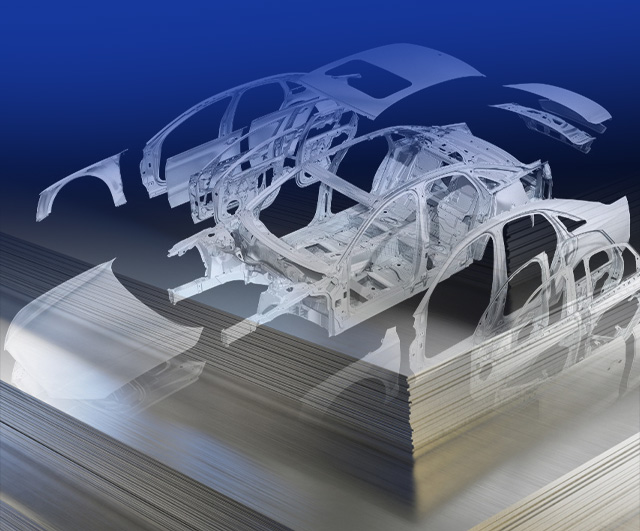

Due to its lightness and good mechanical properties, aluminum is favored by many industries. In the field of automobile manufacturing, with the introduction of the concept of lightweighting, “replacing steel with aluminum” has become very common. Many automobile manufacturers choose to use lighter aluminum materials, whether they are rail vehicles, traditional fuel vehicles or new energy vehicles. Aluminum can promote the lightweight of vehicles, which is beneficial to the transportation industry to achieve a win-win situation of energy saving, emission reduction and economic benefits.

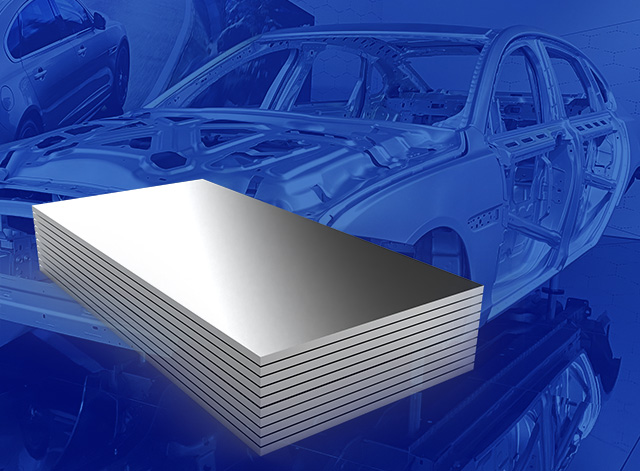

Trucks and refrigerated trucks can use 5-series or 6-series aluminum panels, which have many advantages such as light weight, corrosion resistance, easy processing, and recyclability. 5052 aluminum plate is the most commonly used aluminum plate type in the transportation field. It is an AL-Mg alloy aluminum plate. Magnesium is the main alloy element in the 5052 alloy aluminum plate. It is a widely used anti-rust aluminum.

1. The aluminum alloy is light and high-strength, which can reduce the weight of the carriage and transport more goods.

2. Aluminum alloy has excellent corrosion resistance, weather resistance and long service life.

3. Aluminum alloy has excellent processability and high plasticity.

The new energy vehicle compartment uses 5052 wide aluminum plates and adopts precise sheet metal technology. This can improve the safety of the entire vehicle, making it resistant to bumps, corrosion resistance and long service life.

Mingtai Aluminum produces 5052 ultra-wide aluminum plates for carriages. The width reaches 2600mm. The surface is smooth and clean, without peeling, bubbles, surface roughness and local mechanical damage. There are no cracks, corrosion spots and traces of nitrate salt. Moreover, the performance is stable and reliable, and the effect of later use is good.

Mingtai Aluminum, as a listed company of domestic private aluminum processing enterprises, attaches great importance to the application of products in the automotive industry. It has invested a lot of research and development energy, and many products have been affirmed by auto parts manufacturers. At the same time, the company is also committed to the expansion of aluminum for new energy vehicles. The battery shell materials, battery cover sheets, battery tray materials, liquid cooling plate materials and other products developed have gradually been mass-produced and have been widely recognized by users!

Since aluminum has strong corrosion resistance and does not rust, in theory it can be fully recycled for recycling, and the quality and performance of recycled aluminum is no different from that of original aluminum. When aluminum is recycled, its energy consumption is only 5% of the initial processing energy consumption, which can be described as a green metal that saves energy and reduces emissions.

The price of aluminum is only one-third that of copper, and its proportion is only one-third that of steel. It is an important raw material for consumer goods manufacturing, raw material manufacturing, and equipment manufacturing. From aerospace to catering, from automobiles to cables, aluminum is used more and more widely.

The 5052 aluminum plate is an AL-Mg alloy aluminum plate. This alloy has high strength, especially fatigue resistance, high plasticity, good corrosion resistance, and good weldability. In the event of a violent collision, cracks are unlikely to occur, thus ensuring the safety of the vehicle.