Aluminum foil (PTP) structure for blister packaging: generally expressed as OP protective layer / AL aluminum foil substrate (Mingtai product) / VC adhesive layer;

Aluminum foil has been widely used in pharmaceutical packaging due to its advantages of non-toxicity, high shading, oxygen barrier and moisture resistance. With the advancement of technology, in addition to the traditional aluminum foil (PTP) for blister packaging, aluminum foil is also compounded with various plastics and paper materials as pharmaceutical packaging materials, such as child-safe blister aluminum foil, cold stamping aluminum foil, tropical blister Cover packaging aluminum foil suppository powder composite film, etc.

Aluminum foil (PTP) structure for blister packaging: generally expressed as OP protective layer / AL aluminum foil substrate (Mingtai product) / VC adhesive layer;

Aluminum foil has been widely used in pharmaceutical packaging due to its advantages of non-toxicity, high shading, oxygen barrier and moisture resistance. With the advancement of technology, in addition to the traditional aluminum foil (PTP) for blister packaging, aluminum foil is also compounded with various plastics and paper materials as pharmaceutical packaging materials, such as child-safe blister aluminum foil, cold stamping aluminum foil, tropical blister Cover packaging aluminum foil suppository powder composite film, etc.

Aluminum foil structure for tropical blister packaging: biaxially oriented nylon film BOPA, aluminum foil substrate AL (Mingtai product), heat-sealing adhesive layer VC.

Tropical blister packaging (aluminum-plastic-aluminum) is equivalent to adding a layer of cold-stamped aluminum foil cover on the outside of thermoformed plastic blister and PTP aluminum foil. Blister packaging still adopts vacuum blister forming and keeps the size of the blister unchanged. The area around the blister is slightly wider so that the tropical blister composite film after cold forming can be heat-sealed with the thermoforming blister, which makes up for the traditional The problems of no light blocking and poor water blocking in aluminum-plastic packaging are gradually being accepted by the market.

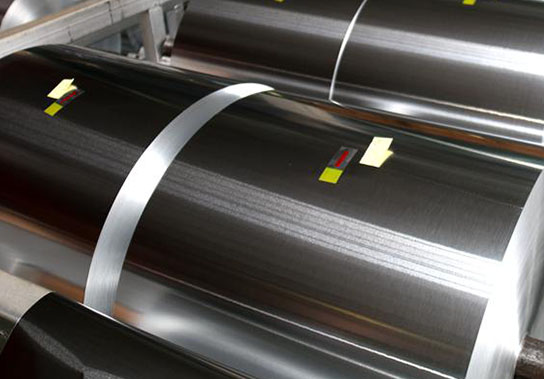

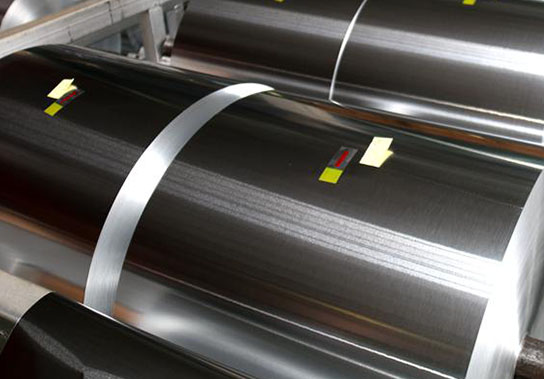

Henan Mingtai Aluminum is Aluminum foil for blister pack for pharmaceutical raw material manufacturers (do not do later lamination, printing, gluing and other processing techniques, only provide aluminum substrates).

Blister medical aluminum foil alloy: 8011 aluminum foil, 8021 aluminum foil, thickness 0.025-0.08mm;

Mingtai Aluminum has a professional R&D and production team, with guaranteed product quality, complete specifications, customized on-demand, complete after-sales service system, rigorous and scientific management, fast production scheduling and timely delivery.

|

Alloy Series |

Alloy |

Temper |

Thickness(mm) |

Width(mm) |

Length(mm) |

|

8xxx series |

8011、8021、8079 |

O、H14、H16、H18 |

0.014-0.2 |

20-1700 |

c |

|

8011 aluminum foil chemical composition (mass fraction) /% |

|||||||||||

|

Alloy |

Si |

Cr |

Cu |

Mn |

Fe |

Zn |

Mg |

Ti |

Others |

Al |

|

|

Each |

Total |

||||||||||

|

8011 |

0.5~0.9 |

≤0.05 |

≤0.10 |

≤0.20 |

0.6~1.0 |

≤0.10 |

≤0.05 |

≤0.08 |

0.05 |

0.15 |

Remain |

|

8021 aluminum foil chemical composition (mass fraction) /% |

||||||||||||

|

Alloy |

Si |

Cr |

Cu |

Mn |

Fe |

Zn |

Mg |

V |

Ti |

Others |

Al |

|

|

Each |

Total |

|||||||||||

|

8021 |

≤0.15 |

. |

≤0.05 |

. |

1.2~1.7 |

. |

. |

. |

. |

0.05 |

0.15 |

Remain |

|

8079 aluminum foil chemical composition (mass fraction) /% |

|||||||

|

Alloy |

Si |

Fe |

Cu |

Zn |

Others |

Al |

|

|

Each |

Total |

||||||

|

8079 |

0.05~0.30 |

0.7~1.3 |

≤0.05 |

≤0.10 |

0.05 |

0.15 |

Remain |