Aluminum plates are frequently used as the main material for door panels. They provide a durable and rigid surface that forms the visible face of the door. Aluminum panels can be flat or have raised or recessed patterns for aesthetic purposes.

Aluminum plates are utilized for constructing frame components of doors. This includes door jambs, stiles, and rails. These frame components provide structural support and help secure the door panels in place.

Aluminum panels are lightweight compared to other materials such as steel or wood. This lightweight nature makes them easier to handle, install, and operate, resulting in improved usability and reduced strain on hinges and hardware.

Aluminum panels have inherent corrosion resistance. They are not susceptible to rust or corrosion, making them ideal for doors exposed to moisture, humidity, or harsh environments. This resistance to corrosion ensures the door’s longevity and reduces the need for frequent maintenance or replacement.

Aluminum panels have inherent corrosion resistance. They are not susceptible to rust or corrosion, making them ideal for doors exposed to moisture, humidity, or harsh environments. This resistance to corrosion ensures the door's longevity and reduces the need for frequent maintenance or replacement.

Aluminum panels are highly recyclable, contributing to sustainable building practices. At the end of their lifecycle, aluminum panels can be recycled and repurposed, reducing waste and minimizing environmental impact.

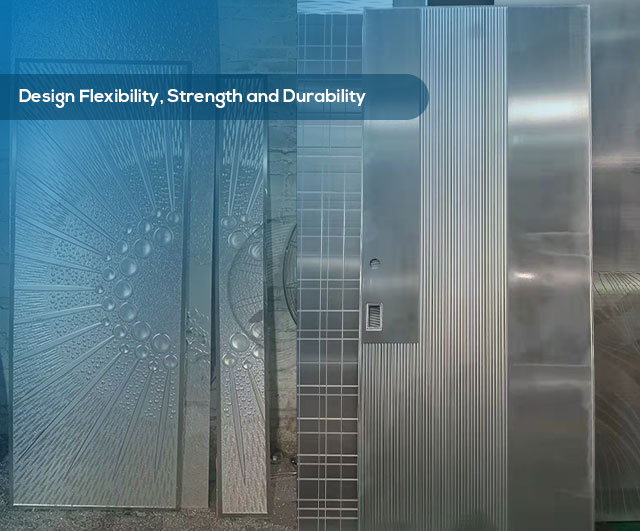

Aluminum panels offer design versatility, allowing for customization and meeting various aesthetic requirements. They can be easily shaped, cut, or formed into different sizes, patterns, or textures, enabling creative door designs and architectural flexibility.

Despite their lightweight nature, aluminum panels are strong and durable. They offer excellent structural integrity and can withstand daily wear and tear, providing long-lasting performance. They are resistant to warping, cracking, and rotting, ensuring the door maintains its functionality and appearance over time.

Aluminum panels can provide effective sound insulation when combined with appropriate insulation materials. This helps to reduce noise transmission, creating a quieter and more peaceful environment inside the building.

Aluminum alloy sheet has good formability, high plasticity and easy processing.

The price of aluminum plate mainly needs to combine multiple factors such as aluminum ingot price, processing fee, freight and so on.

The price of aluminum ingots is the average closing price of the Yangtze River spot aluminum ingots on the day of delivery. The price of aluminum in the market fluctuates every day, so the quotation will be slightly different.

The processing cost of aluminum plate is mainly determined by the thickness, width and state of the product. The price of the product is different with different specifications.

Logistics transportation is an important part of product sales. The length of transportation distance and the quantity of goods will affect the freight price. Generally, the logistics system of large formal manufacturers is relatively complete and developed, so the transportation cost is relatively low.

The use of aluminum sheets for doors and windows is also a common architectural decoration application.

|

Item types |

Aluminum for doors |

|

Alloy |

5052 |

|

Thickness |

0.15--600mm |

|

Width |

100--2650mm |

|

Application |

Aluminum alloy door panels, carved panels, roof panels, stair railings, screens, etc. |