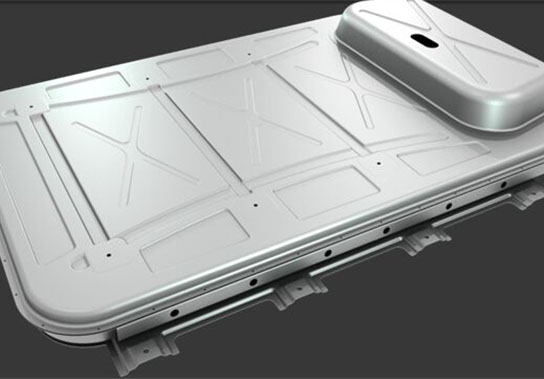

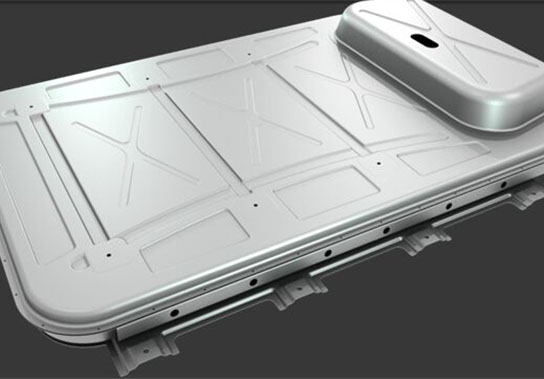

Under the background of low carbon, new energy has become the main direction of global development. With the explosive growth of production and sales of new energy vehicles in my country, the demand for lithium batteries has been continuously rising. Battery PACK is the core energy source of new energy vehicles, providing driving power for the entire vehicle. As the core component of new energy vehicles, its quality directly determines the performance of the vehicle.

Under the background of low carbon, new energy has become the main direction of global development. With the explosive growth of production and sales of new energy vehicles in my country, the demand for lithium batteries has been continuously rising. Battery PACK is the core energy source of new energy vehicles, providing driving power for the entire vehicle. As the core component of new energy vehicles, its quality directly determines the performance of the vehicle.

Due to its light weight and high thermal conductivity, aluminum materials are mainly used in the upper box (cover), lower box (battery tray), side panels, water cooling system (liquid cooling plate), battery module (battery shell) etc. The exterior design of EV battery enclosures is mainly considered from multiple aspects such as material and anti-corrosion performance.

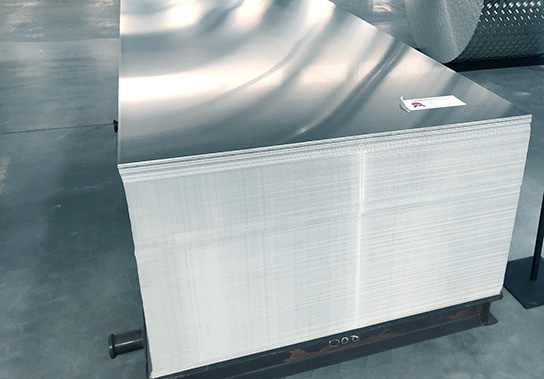

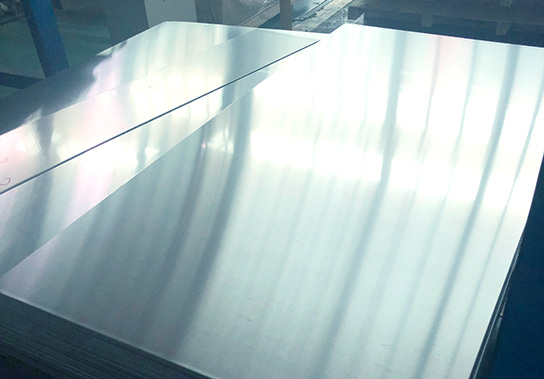

Under the background of automobile lightweight, new energy, and sustainable application materials, Mingtai Aluminum has actively developed and produced aluminum plate materials for pack boxes. As a private listed aluminum processing enterprise in Henan, Mingtai Aluminum is actively deploying. At present, the aluminum plate materials for power battery pack boxes have achieved mass production.

3003 alloy aluminum plate is a new material that is very suitable for EV battery enclosures after many experiments in terms of performance and composition. The 3003 aluminum plate produced by Mingtai Aluminum Industry strictly selects materials and controls the production process. The performance of the product meets the requirements of EV battery enclosures.

The 5083/3003 aluminum plate has good corrosion resistance, is durable, and plays an important role in the lightweight of the transportation field.

The preparation of EV battery side plate 5083-o/3003 is mainly through smelting-ingot casting-heat treatment-hot rolling-cold rolling...and many other processing links, and its performance advantages are more prominent:

Henan Mingtai Aluminum Co., Ltd. is a manufacturer with more than 20 years of production experience. It has a standardized production plant with strict raw materials and workmanship. Some products are available from stock, and there is no middleman to make the difference. For the specific price of the new aluminum sheet for EV battery enclosures, welcome to consult online. And there are professional technical managers to customize the plan for free, the product quality is guaranteed, and the service is relatively perfect.