Pharmaceutical packaging aluminum foil has become a new type of pharmaceutical packaging widely used in the world. Mingtai Aluminum is a large-scale manufacturer of pharmaceutical packaging aluminum foil substrates. The 8011 pharmaceutical aluminum foil, 8021 pharmaceutical aluminum foil, and 8079 pharmaceutical aluminum foil produced by the company have undergone strict standards. Pore detection, degreasing process and plate shape control ensure that the produced pharmaceutical aluminum foil can achieve ultra-high sealing performance in the later adhesive compounding process and perfectly protect the quality of pharmaceuticals.

It has been proved by the practice of major pharmaceutical packaging material manufacturers that Mingtai’s pharmaceutical packaging aluminum foil meets the production requirements and the performance meets the standards.

8011 aluminum foil is used for pharmaceutical packaging: PTP pharmaceutical aluminum foil, cold stamping pharmaceutical foil, 8011-H18 pharmaceutical packaging aluminum foil, capsule aluminum foil, etc. Advantages: high cup convexity, high aluminum foil strength, and good sealing;

It has excellent moisture resistance, shading advantages and high blocking ability. Strong mechanical properties, good shear and tensile properties, easy to process. It has good corrosion resistance and has a certain ability of stress corrosion cracking. The products produced by Mingtai are of high quality, with a clean and shiny surface.

8021 aluminum foil is one of the key products of Mingtai Aluminum. The thickness range of production is 0.018mm-0.2mm, and the width can be controlled at 100-1650mm according to customer requirements.

Cold-formed aluminum overcomes the deficiencies of conventional medical PVC hard sheets and PP hard sheets in terms of moisture resistance, gas insulation, light protection, and thermal stability. It is a drug that isolates various gases and blocks light radiation. Blister type material for packaging. It can effectively prolong the shelf life of medicines and can be used as medicine packaging materials in extreme (high/low temperature) environments.

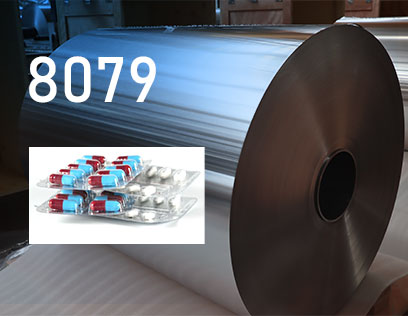

8079 aluminum foil has high strength, excellent elongation and compression performance, and is easy to form. The layout requirements are strict, the layout is flat, the porosity is guaranteed when cutting, and the brushing water can reach the A-level standard. It is not easy to deform under high and low temperature conditions, and has the characteristics of shading, airtight, non-toxic and tasteless. The surface has a silver-white luster, and it is easy to process beautiful patterns and patterns of various colors. Mingtai Aluminum can produce 8079 aluminum foil of O, H22, H24 temper.

If you are looking for tailgate inserts material in the market, then Mingtai Aluminum will be your best friend. Mingtai Aluminum provides aluminum sheet for tailgate inserts.

1060 aluminum foil is widely used to make gaskets due to its high plasticity, corrosion resistance, electrical conductivity and thermal conductivity. With heat seal to PVC. The appearance is novel and enhances the competitiveness of medicines. Good printing and coloring, rich colors and clear patterns.

Aluminum foil can effectively prevent medicines from moisture and humidity, and can keep medicines dry and stable. In addition, aluminum foil can also prevent oxygen and other gases from entering pharmaceutical packaging, thereby maintaining the stability and active ingredients of pharmaceuticals. Some pharmaceuticals deteriorate when they come in contact with oxygen, so aluminum foil can help protect their quality.

Aluminum foil is an excellent thermal insulator that can help preserve the active ingredients and potency of pharmaceuticals. Medicines usually need to be stored at low temperatures, and aluminum foil can protect medicines from high temperatures.

Aluminum foil can make pharmaceutical packaging easier to read and identify. At the same time, aluminum foil can also be used in anti-counterfeiting packaging to ensure the authenticity and safety of medicines.

Aluminum foil can be sealed by heat sealing or cold sealing technology to ensure the airtightness of pharmaceutical packaging. This can help protect pharmaceuticals from external contamination and oxidation.

Here are some common types of pharmaceutical packaging aluminum foil

|

Usage |

Alloy |

Temper |

Thickness(mm) |

Width(mm) |

Typical Product |

|

PTP Pharmaceutical Packaging |

8011 |

H18 |

0.016-0.5 |

200-1600 |

Capsule medicine cover, etc. |

|

Blister Pharmaceutical Packaging |

8021 |

O |

0.04-0.065 |

200-1600 |

Blister packaging, etc. |

|

Tropical Pharmaceutical Packaging |

8021,8079 |

O |

0.016-0.2 |

200-1600 |

High-end pharmaceutical packaging |

|

Medicine Bottle Cap |

8011 |

H14、H16 |

0.016-0.5 |

200-1600 |

Oral liquid aluminum-plastic composite cap, infusion bottle aluminum-plastic cap, etc. |

|

Gasket |

1060 |

O、H18 |

0.014-0.2

|

200-1600 |

Pharmaceutical packaging gasket |