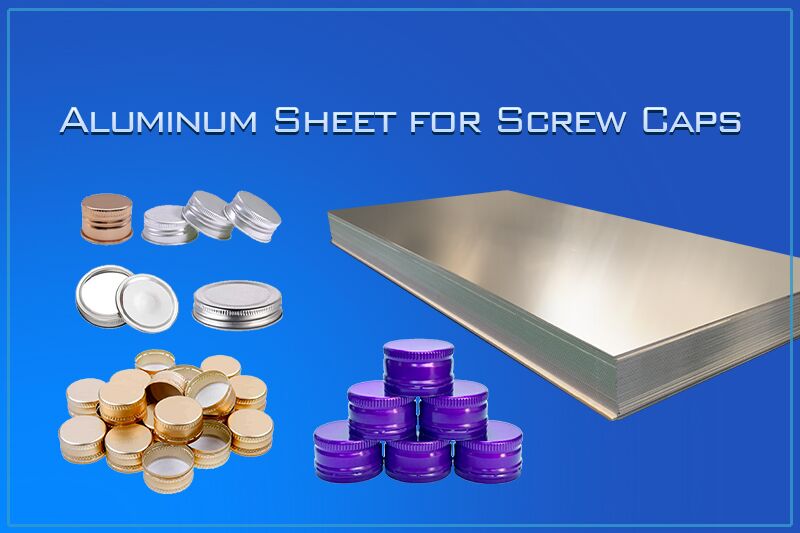

In modern packaging, threaded caps are essential components for beverages, food, pharmaceuticals, and cosmetics. Their performance is crucial for product safety, shelf life, and user experience. The foundation of a high-quality cap lies in its raw material – the aluminum sheet. A superior aluminum sheet is the invisible guardian ensuring perfect sealing, smooth opening, and an impeccable finish for screw caps. This article details the core requirements for aluminum in cap manufacturing and provides a practical selection guide.

Cap manufacturing involves precision stamping, demanding a specific set of properties from the aluminum strip:

When selecting aluminum for screw caps, manufacturers should focus on these technical parameters:

* 8011 Alloy: Specifically designed for packaging, this alloy contains small amounts of iron and silicon. It offers an excellent balance, maintaining great formability and deep-drawing performance while providing higher strength and rigidity than pure aluminum alloys. Its stability after forming makes it a classic, widely-used choice for screw caps.

* 3105 Alloy: An enhanced version of 3003 alloy, 3105 contains manganese and magnesium, offering higher strength and superior corrosion resistance. It has a lower work-hardening rate, retaining good ductility after stamping. It is ideal for caps requiring extra strength, higher internal pressure resistance, or frequent opening (e.g., carbonated beverage caps, large lids), and offers better resistance to aggressive contents.

* H14 or H24 temper is the standard choice. This “half-hard” condition, achieved through partial annealing after cold rolling, perfectly balances excellent stamping formability with the final strength required for the finished cap. It helps minimize springback, ensuring stable thread formation.

* Common thickness ranges from 0.20mm to 0.30mm. More critical than the absolute value is strict tolerance control. Top-tier suppliers provide material with thickness tolerances as tight as ±0.01mm, which is essential for consistent, high-quality production.

* Depending on the downstream coating process, aluminum with different surface oil levels (e.g., low oil, dry) or specific roughness can be selected. Clear communication with your supplier about your production process ensures you get the most suitable material.

Given the stringent demands of screw cap production, choosing a raw material partner with strong technical expertise and strict quality control is vital. Mingtai Aluminum, a specialist in aluminum sheet and strip manufacturing, provides stable and reliable solutions for global cap makers:

* Superior Product Consistency: Our fully integrated, intelligent production process—from molten metal purification and homogenization to precision cold rolling—ensures highly stable mechanical properties and chemical composition for every coil and batch, safeguarding your continuous mass production.

* Precise Dimensional Control: Advanced rolling and inspection technologies guarantee industry-leading thickness tolerance, width, and flatness, significantly reducing setup waste and downtime in your stamping operations.

* Clean, Perfect Surface: We maintain strict control over roll cleanliness, rolling oils, and the production environment, delivering defect-free surfaces that provide the perfect base for high-quality printing.

* Expert Technical Support: We offer more than just product. Our technical team provides professional material selection advice, helping you choose between alloys like 8011 and 3105 to optimize the balance between cost and performance.

Choosing Mingtai Aluminum’s high-quality aluminum sheet for screw caps is a strategic decision to ensure superior sealing, aesthetics, and market competitiveness from the very source. Rely on Mingtai Aluminum for consistent performance and exceptional service as your trusted strategic partner in raw materials.

Q1: What are the most common aluminum alloys for screw caps?

A: 8011 alloy is the most common and versatile choice. 3105 alloy is used for applications requiring higher strength.

Q2: What is the main difference between 8011 and 3105 alloys?

A: 8011 offers superior formability for general use. 3105 provides higher strength and better corrosion resistance for demanding applications like carbonated drinks.

Q3: How can I ensure the aluminum is suitable for high-speed stamping?

A: Strict thickness tolerance, excellent flatness, and consistent mechanical properties are key to efficient, high-yield stamping production.

Q4: Can Mingtai Aluminum provide food-safe aluminum sheet?

A: Yes, our products comply with relevant food safety and industry standards for packaging applications.