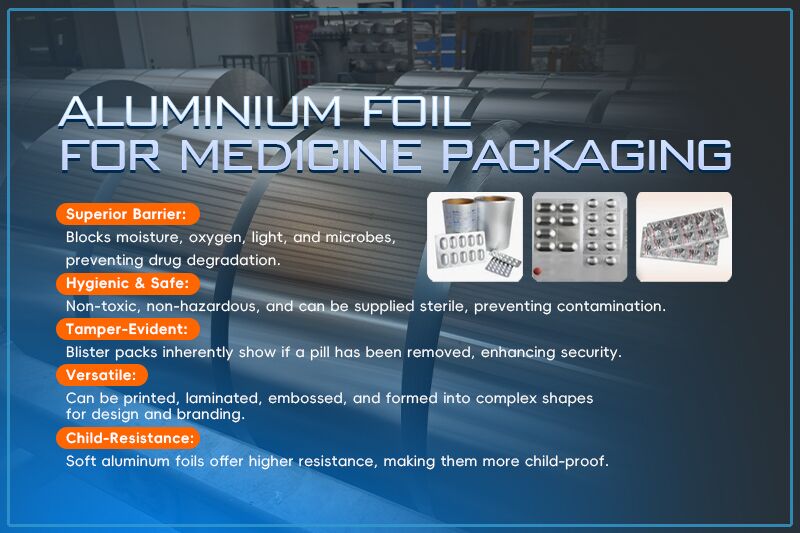

In the modern pharmaceutical industry, the stability and safety of medicines depend directly on their packaging. Exposure to light, oxygen, moisture, and even microbes can lead to reduced efficacy or safety risks. Therefore, the choice of the core barrier layer—the primary packaging material, specifically aluminium foil for medicine packaging—is critical. It serves not only as a physical shell but also as the first line of defense in ensuring patient safety and meeting stringent global regulations.

The core value of pharmaceutical aluminium foil lies in its near-perfect barrier performance.

– 100% Light Barrier: Effectively protects light-sensitive drug components from photodegradation.

– Excellent Oxygen and Moisture Barrier: Extremely low water vapor and oxygen transmission rates guarantee the absolute stability of drug components throughout the shelf life.

– Total Contamination and Microbial Barrier: The dense metallic structure blocks microbes, dust, and other gases, ensuring product sterility.

This comprehensive protection is difficult to achieve with other single materials. Mingtai Aluminum‘s hard-temper aluminium foil, with its higher strength and denser crystalline structure, maximizes this barrier effectiveness.

“Pharmaceutical-grade” is not a general term but a set of mandatory standards. Compliant foil must meet:

– International Pharmacopoeia Standards: Such as relevant requirements of the United States Pharmacopeia (USP) and European Pharmacopoeia (EP).

– Regulatory Certifications: Production systems should align with relevant FDA requirements and strict certifications like ISO 15378 (Quality Management for Pharmaceutical Packaging Materials).

– Material Safety: Ensuring very low levels of volatiles and extractables to avoid any interaction with the drug product, and being inherently non-toxic and harmless.

A supplier’s Quality Management System and production environment are key review points. Mingtai Aluminum controls critical production steps in a GMP-compliant clean environment and provides complete compliance documentation, smoothing the path for client drug applications and global market access.

Different dosage forms have specific requirements:

How to choose precisely amid diverse needs? Consider these key parameters:

– Thickness (μm): Typically between 20-40μm. Thicker foil offers better barriers but at a higher cost; balance is needed based on drug sensitivity, packaging machinery compatibility, and budget.

– Mechanical Properties: Tensile strength, elongation, and burst strength directly impact the operational efficiency and yield of high-speed automatic packaging lines. Stable-performance foil can significantly reduce downtime and waste.

– Surface Characteristics:

– Printability: Surface tension must support high-quality branding and printing.

– Coating Performance: The adhesion and uniformity of protective and heat-seal coatings directly determine final seal quality and shelf life.

– Defect Control: Microscopic defects like pinholes, uneven gloss, or coil curl are unacceptable. Their absence is a direct reflection of a supplier’s process control capability.

Matching the most appropriate alloy temper, thickness, and surface treatment to different dosage forms and applications is key to packaging performance. Mingtai Aluminum’s detailed Technical Data Sheets (TDS) and tailored consultation services can help you make optimal technical decisions efficiently.

Mingtai Aluminum specializes in providing high-performance, compliant, and reliable primary packaging materials, including pharmaceutical-grade aluminium foil. With strict process control and deep industry expertise, we are committed to being the trustworthy foundation of your supply chain. Explore our specialized product series for pharmaceutical packaging foil for detailed specifications, or contact our technical support team for a targeted solution.

Frequently Asked Questions (FAQ)

Q: What is the typical thickness range for pharmaceutical aluminium foil?

A: Typically 20-40 micrometers. The optimal choice balances barrier needs, machine compatibility, and cost.

Q: How can I ensure the foil meets pharmaceutical packaging regulations?

A: Partner with a certified supplier like Mingtai. We provide compliant materials and full documentation (e.g., for FDA, USP/EP) to support your regulatory submissions.

Q: Can you provide customized specifications?

A: Yes. We offer customization in alloy, thickness, width, mechanical properties, and surface treatment to meet your project’s specific requirements.

Q: What about the sustainability of aluminium foil packaging?

A: Aluminium is infinitely recyclable without quality loss. Properly recycled foil packaging supports strong environmental sustainability goals.